home > Engineering Services > Retrofit and Maintenance of Existing Lines

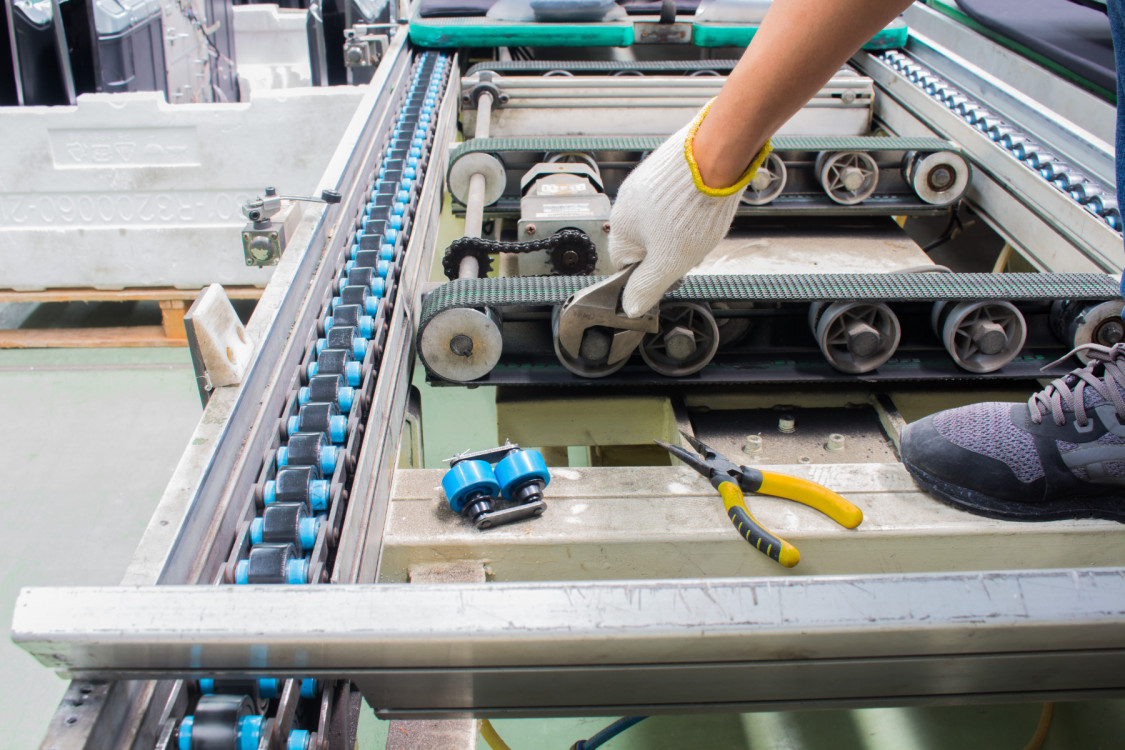

Retrofit and Maintenance of Existing Lines

Our know-how

Thanks to our long experience in different industry domains, we can evaluate and propose Taylor-made solutions for modifying, refurbishing, updating and relocating the exiting lines, to meet any needs that may arise during the life of the production line, changes and implementations. To improve efficiency and performances.

- Analysis and audit of the existing lines by our technicians

- Analysis of customer needs

- Overall feasibility study

- Consultation and study of the equipment maintenance /upgrade required to achieve the objective

- Definition of spaces, handling of materials, logistics

- Preliminary general project including machines and “to do list “ of necessary actions to achieve the objective

- Identification of the auxiliary services

- Plan development

Our Engineering Department

Our engineering department can study and develop the best possible product flow handling solutions via conveyors, FIFO/mass-flow accumulation tables and elevators–taking into account any production requirements (accumulation, alignment, production rate, stability of the containers to be handled, footprint optimization).

We can also examine and solve any industrial automation problems through the implementation of end-of-line solutions complete with secondary packaging machines and robotic palletizers.

In addition to that, leveraging on the long-time experience acquired in multiple sectors, we are able to provide engineering services, technical consulting and feasibility studies. Focusing on the optimization of the manufacturing processes, we design and develop customized line layouts tailored to customers’ needs.

Finally, we can also retrofit, revamp or upgrade existing packaging machines, or at your premises or in our manufacturing plants, to enhance performance or add new features.

The advantages of choosing CIAM PACK

Our know-how has developed over the years in collaboration with our customers, allowing us to be today a reference for the manufacture of: product flow management systems, packaging machines, special and robotic machines and services engineering.

We are at your disposal for:

- Consulting services and designing of new plants and installations

- Supply of complete turnkey solutions from a sole contractor

- Evaluation of the packaging and palletizing processes required to implement the project